Overview of furniture screws, design features and scope

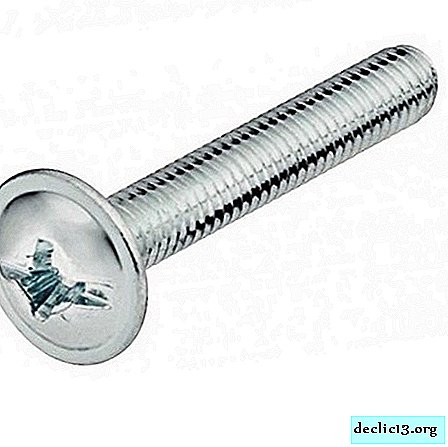

Features of the materials used in the furniture industry imply the use of a variety of mounting hardware. Its range is very extensive, and high-quality assembly is impossible without fasteners that correspond to a specific task. Furniture screw is the most popular representative of connecting elements in the production of upholstered and cabinet furniture. Its popularity is due to a wide range of applications, reliability of fixation, ease of installation and moderate cost.

Scope of application

As the name implies, the main purpose of this fastener is furniture production. Naturally, the application is not limited to this, and screw fasteners are used in many sectors of the national economy, as well as for solving everyday problems. Depending on the size and design, the following options for using this fastener can be distinguished:

- The connection of the panels of the laminated chipboard during the assembly of cabinet furniture;

- Assembly of frames in the manufacturing process of beds, sofas, armchairs and other upholstered furniture;

- Pairing parts from solid wood in carpentry and construction.

Some types of screws have a fairly narrow scope. For example, shelf holders with locks are designed solely to hold shelves. At the same time, without such fasteners as a confirmation, not a single cabinet or bedside table can do. And the use of bolts, in addition to their main purpose, is common in areas quite distant from the furniture industry.

Varieties

Use cases depend on the purpose and design of the particular fastener. Next, we consider the most common varieties of furniture screws and how to use them.

Euroscrew (confirmation)

Structurally, it is a cylindrical part with a countersunk head, in which there are slots for a hexagon or Phillips screwdriver. Immediately after the countersunk head there is a smooth part, which should freely enter the pressable workpiece. The size of the smooth part is different and depends on the purpose of a particular screw. For example, the standard thickness of a laminated chipboard is 16 mm. To normally pull one sheet of chipboard or the same thickness material, it is enough to use fasteners, the smooth part of which is 16 mm. For these tasks, furniture screws with a diameter of 7 mm and a length of 50-60 mm are most often used.

Application technology involves drilling workpieces. This is due to the characteristics of the material, which is most often used in the furniture industry (particleboard). The thickness of the confirm does not allow it to be twisted into a chipboard without drilling. The drill used in the preparation of parts for the connection has a special configuration and is different in diameter in different areas.

Theoretically, you can drill with three different drills:

- The largest radius is designed to make a hole under the confirm hat; in fact, this part of the tool does not make a hole, but merely removes the chamfer.

- Next, a hole is made in the pressed workpiece, its diameter is equal to the smooth part of the Euroscrew (for example, 7mm).

- The thinnest hole is drilled in the part to which the previous one is pressed, its diameter is 5 mm.

Using three drills is not very convenient: they need to be changed or have three drills in which the required diameter will be installed. In addition, manual potting with a drill is quite difficult. Given these factors, one special drill has been developed, which modern furniture makers use. When the preparatory work is over, the workpieces are pulled together by screws. The tool for twisting the latter is selected depending on the design of the cap.

If the most popular confirm size is 7x50 mm, then the most common slot configuration is hexagon. The following tools are used to tighten the hexagon head screws:

- Hex bit, for use in a screwdriver, drill or screwdriver;

- L-shaped or z-shaped hex key;

In addition to hexagonal slots, there are still cross slots, but their use does not allow to tighten the parts tightly enough, which leads to an early loosening of the finished product.

Screw coupler

It consists of two elements: a screw with an external thread and a barrel-nut with an internal. In the process of joining, the parts are perpendicular to each other, that is, one workpiece with the flat side pressed against the end of the other workpiece. A through hole is drilled in the pressed part, the diameter of which is slightly larger than the threaded part of the screw. In the blank to which the previous one is pressed, two holes are drilled: one from the end face with the same diameter as in the pressed part; the other on the flat side is for the barrel. The difficulty lies in the exact combination of the end hole and the hole for the barrel.

As with the Euroscrew, the main direction of use of this fastener is furniture production. Using a screw tie, you can achieve significant structural rigidity, which is not available when using any fasteners without metric threads, for example, confirmats or self-tapping screws.

The weaknesses of this connecting material are installation difficulties that require certain skills, as well as the visibility of the furniture screw head from the outside. The last drawback can be partially hidden using special stubs, but this does not completely solve the problem.

Conical Screed (Mini Fix)

To install a conical coupler, you do not need to drill through a part that is fastened with the flat side. The mechanism of operation is somewhat similar to a screw coupler. The difference in the fixation of the rod: it is mounted not in the through hole, but in the flat part of the clamped workpiece (after preliminary drilling). The parts are fastened together by pressing the rod with a tie screw. This type of connecting elements is often used to fasten countertops to the base or during the assembly of furniture-type facade facades.

Conical couplers are also not easy to install, require precise marking and drilling, which implies the high qualification of the collector. In addition, silumin used for the manufacture of a tightening screw has a small operational resource, which significantly reduces the number of assembly / disassembly cycles of the finished product. Such a joint in most situations is disposable, in any case, for reassembly will have to replace the tightening screw from silumin.

Fixing shelves

This type of fastener is designed to hold shelves in furniture products. Its feature is that in parallel with the main purpose (support for shelves), it provides additional structural rigidity. The shelf holder consists of two parts: a rod and a support mechanism. The stem is screwed into the cabinet wall, and the support mechanism is installed directly in the shelf. During assembly, the stem should fall into the hook of the eccentric mechanism. After that, the shelf is attracted to the cabinet walls by turning the eccentric screw in the shelf holder.

This type of hardware is also not easy to install, it requires specialist skills and the availability of special equipment. In addition to marking and drilling, installation will require milling, which is best done in the workshop on a drilling machine.

Intersection Screed

Designed to connect individual furniture modules. In fact, this is a bolt and nut, only in a more aesthetic design. The part of the coupler, which acts as a nut, is made in the form of a hollow bolt (sleeve) with an internal thread into which a movable tightening element is screwed. During the assembly process, it is precisely the screw (an element with an external thread) that needs to be tightened, and not the sleeve, since there are slots on it that prevent it from rolling in the chipboard wall.

A fairly simple to use and reliable furniture screw, as a rule, is made of high-quality metal, provides a rigid bundle of individual sections in the furniture industry. Often used in the assembly of kitchen sets, in particular wall cabinets. Intersection screed turns individual cabinets into a solid monolithic wall, eliminating the appearance of differences between kitchen units during operation.

Furniture screw with a semicircular or decorative head

The classic threaded connection is used for upholstered and cabinet furniture. There are several varieties of this fixture, the main distinguishing features of which are the design of the head and fixing elements. The fixing of the screw in the chipboard is carried out by means of a square headrest or slots. Such fasteners are quite convenient to use, since the nut can be screwed on without resorting to additional fixation of the screw itself. There are also options designed to hold a screwdriver or hexagon.

Furniture screws are distinguished by size, material of manufacture and type of head. Let us consider in more detail each of the above types.

Semicircular

Semicircular Decorative

DecorativeTo size

- Furniture screed is produced in accordance with the most commonly used material, i.e. laminated particleboard, whose thickness is 16 mm. Given that the coupler connects two plates drilled through, the length of one is 32 mm. This is the most requested size, but there are also options with a length of 50 mm;

- Euroscrew is 5, 6.3 and 7 mm thick. Moreover, its length can be 40, 50, 60 and 70 mm. The lengths of 60 and 70 mm are found only in 7 mm confirmations;

- The dimensions of the conical screed are standard; total length 44 mm; diameter 6 mm;

- The length of the screw tie is 34 mm, while the diameter of the barrel is 10 mm, and the screw itself is 8 mm;

- The length and diameter of the screws with a semicircular or flat head can be different and depends on the type of locking element. For example, hexagon screws are 6 or 8 mm in diameter, 16 to 110 in length. The maximum length of furniture bolts for a screwdriver or with a square headrest is 150 mm, with a standard diameter of 6 and 8 mm.

According to the material of manufacture

The purpose of this type of fixing materials is to fix the furniture structure of varying degrees of rigidity. In addition, the finished product should look no worse than that of competitors. To achieve the optimum ratio of the monolithic structure and its appearance, the following materials are used:

- Metal fasteners made using carbon steel grades;

- Aluminum and its alloys (silumin) - used in the elements of screws of complex configuration, for example, a tightening screw mini-fix;

- Brass is a more aesthetic and practical material. Applied in visible areas of structures or in places with high humidity;

- Plastic is used as a case material in the seats of some types of screeds such as a shelf holder body;

Metal fasteners for furniture can be coated or uncoated (most often galvanized), but in any case, the products are regulated by GOST or other standards.

By type of head, there are the following types of furniture screw heads:

- Spherical flat head without internal splines for holding with an external locking tool. Typically, such fasteners have a square headrest or fixing mustache. Basically, these are all furniture screws DIN 607;

- Spherical head for hexagon, flat or Phillips screwdriver. The most common representative of this type of fastener is a screw with a press washer DIN 967;

- A flat head for a Phillips screwdriver or hexagon, for example, a screw that complies with DIN7420;

- Countersunk head for hexagon or cross bit (confirmations and some types of threaded fasteners).

Steel

Steel Aluminum

Aluminum Brass

BrassCoatings Used

Furniture fasteners are used in the vast majority of cases indoors, which protects it from the harmful effects of the environment. Nevertheless, all metal elements made of steel susceptible to corrosion undergo special treatment:

- Galvanizing gives metal fasteners higher functional and decorative qualities. In most cases, this is a white, matte finish, less often with a golden hue;

- Brass plating. Unlike galvanizing, this coating provides a more attractive appearance, which is achieved by adding copper to the coating alloy.

The above technologies for applying zinc and copper alloys to fasteners are designed to provide higher performance and decorative qualities. The elements of screws made of aluminum are almost never covered with protective compounds, which is due to the properties of the material from which they are made.

Galvanized

Galvanized Brass

Brass